The transition to a circular economy represents a significant shift in business operations, moving away from linear “take-make-dispose” models towards systems that emphasize reuse, repair, remanufacturing, and recycling. This playbook outlines a structured approach for businesses to integrate circular economy principles, fostering sustainability, resilience, and economic advantage.

Understanding the Circular Economy Paradigm

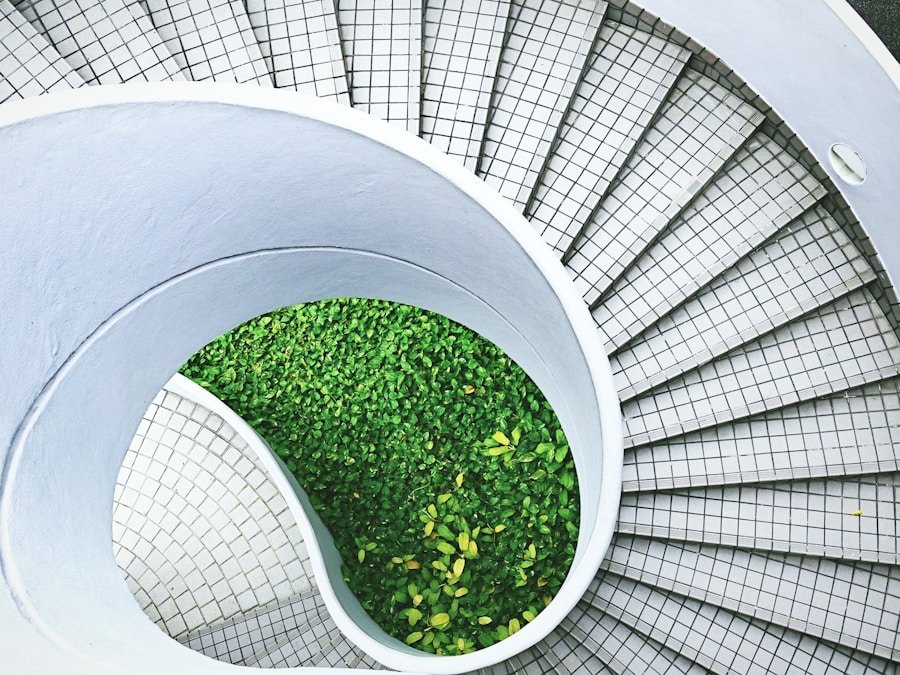

The circular economy is an economic model that aims to eliminate waste and pollution, keep products and materials in use, and regenerate natural systems. It is a departure from the traditional linear model, where resources are extracted, manufactured into products, used, and then discarded. In contrast, a circular economy envisions a closed-loop system where resources are continuously cycled, minimizing environmental impact and maximizing resource efficiency.

The Linear vs. Circular Model: A Fundamental Difference

The linear economy operates on a “cradle-to-grave” philosophy. Raw materials are extracted, processed into products, used once, and then sent to landfills or incinerators. This model is inherently unsustainable due to finite resource availability and the accumulation of waste. The circular economy, conversely, adopts a “cradle-to-cradle” approach. Products are designed for durability, repairability, and eventual disassembly, allowing their components and materials to re-enter the production cycle. This approach treats waste not as an endpoint but as a valuable resource.

Core Principles of Circularity: The Building Blocks

Several key principles underpin the circular economy. Firstly, designing out waste and pollution is paramount. This involves rethinking product design from the outset to eliminate problematic materials, maximize longevity, and facilitate easy disassembly. Secondly, keeping products and materials in use focuses on extending the lifespan of goods through various strategies like repair, refurbishment, and remanufacturing. Thirdly, regenerating natural systems acknowledges the interconnectedness between economic activity and the environment, aiming to restore and enhance ecological health. These principles are not isolated but work in synergy to create a robust and sustainable economic system.

Benefits of Adopting Circular Strategies: More Than Just Greenwashing

The adoption of circular economy strategies offers a multifaceted array of benefits. Economically, it can lead to reduced operational costs through material savings and more efficient resource utilization. It can also foster new revenue streams by creating markets for secondary materials, refurbished products, or product-as-a-service models. Environmentally, the benefits are clear: reduced greenhouse gas emissions, less landfill waste, and conservation of natural resources. Moreover, it can enhance brand reputation and customer loyalty by appealing to environmentally conscious consumers and stakeholders. A business that embraces circularity can become more resilient to resource scarcity and supply chain disruptions, akin to a well-fortified fortress against unpredictable storms.

Step 1: Assessing Your Current Business Model and Material Flows

The initial phase of transitioning to a circular economy involves a thorough examination of your existing business operations and how materials move through your value chain. This diagnostic exercise is crucial to identify opportunities for improvement and to establish a baseline for measuring progress.

Mapping Your Value Chain: From Source to Sink

Begin by meticulously mapping your entire value chain, from the sourcing of raw materials to the end-of-life management of your products. This process involves identifying all stages where materials are procured, transformed, transported, used, and ultimately disposed of. For each stage, document the types of materials consumed, the quantities involved, and the associated environmental impacts. This mapping exercise can be visualized as charting a river’s course, identifying every tributary and delta that contributes to its flow.

Material Flow Analysis: Identifying Bottlenecks and Waste Streams

Once the value chain is mapped, conduct a detailed material flow analysis. This involves quantifying the inputs and outputs at each stage, identifying where materials are lost, degraded, or become waste. Look for opportunities to minimize material consumption, substitute hazardous substances, and recover valuable materials from waste streams. This analysis is like a doctor performing a thorough check-up, pinpointing areas of inefficiency and potential illness within the business’s metabolic processes.

Life Cycle Assessment (LCA): Understanding Product Footprints

A Life Cycle Assessment (LCA) can provide a comprehensive understanding of the environmental impacts associated with your products or services throughout their entire life cycle. This includes impacts from raw material extraction, manufacturing, distribution, use, and end-of-life disposal. LCA helps identify “hotspots” – stages with the most significant environmental burdens – guiding your circularity efforts towards areas where they will have the greatest positive effect. Think of LCA as a detailed environmental X-ray, revealing the hidden stresses on the system.

Identifying Existing Circular Practices: Building on Strengths

Before introducing new initiatives, identify any existing practices within your organization that align with circular economy principles. This could include recycling programs, repair services, or take-back schemes. Recognizing and leveraging these existing strengths can provide a solid foundation for further transformation and demonstrate internal buy-in. It’s about finding the seeds of circularity that may already be present, ready to be cultivated.

Step 2: Redesigning Products and Services for Circularity

Once you have a clear understanding of your current material flows and impacts, the next critical step is to redesign your products and services to be inherently circular. This involves a fundamental shift in how you conceptualize and create offerings.

Design for Durability and Repairability: Extending Product Life

Products should be designed with longevity in mind. This means choosing durable materials, employing robust construction techniques, and ensuring that components can be easily accessed and replaced. Design for repairability involves making it straightforward for users or repair technicians to fix common issues, thereby extending the usable life of the product. Consider a well-built piece of furniture, designed to last generations, rather than a disposable item.

Modularity and Standardization: Facilitating Reuse and Upgrading

Designing products with modular components allows for easier replacement of worn-out parts or for upgrading with newer technologies without discarding the entire product. Standardization of these modules across different product lines can further enhance efficiency and create economies of scale for repair and remanufacturing. This is akin to using interchangeable LEGO bricks; individual pieces can be replaced or upgraded, keeping the overall structure functional and relevant.

Material Selection and Substitution: Prioritizing Recycled and Renewable Content

The choice of materials is central to circularity. Prioritize the use of recycled content and renewable, bio-based materials wherever possible. Furthermore, avoid materials that are difficult to recycle, hazardous, or contribute to pollution. Designing with disassembly in mind also means avoiding complex material composites that are hard to separate. This is a conscious choice to build with ingredients that can be returned to the earth or re-purposed indefinitely, rather than those that leave a toxic legacy.

Developing Product-as-a-Service (PaaS) Models: Shifting Ownership and Responsibility

Product-as-a-Service models transition the focus from selling a product to selling the use or performance of that product. For example, instead of selling a washing machine, a company might offer a laundry service. This incentivizes the provider to design durable, easily repairable products, as they retain ownership and are responsible for their maintenance and end-of-life management. This fosters a strong partnership between the provider and the user, both invested in the longevity and optimal functioning of the “service.”

Designing for Disassembly and Re-entry into the Cycle

Products should be designed so that they can be easily taken apart at the end of their useful life. This facilitates the separation of materials for recycling, remanufacturing, or reuse. Avoid permanent seals, adhesives that are difficult to break, and complex integrated components that hinder disassembly. This ensures that when a product has fulfilled its purpose, its constituent parts can embark on a new journey, not an abrupt end.

Step 3: Implementing Circular Business Models and Strategies

With redesigned products and services, the next stage is to embed these circular principles into your overarching business strategy and operational models.

Establishing Reverse Logistics and Collection Systems: Closing the Loop

Efficient reverse logistics systems are essential for bringing used products and materials back into the value chain. This involves setting up collection points, transportation networks, and processing facilities to handle returns, repairs, remanufacturing, and recycling. The effectiveness of these systems directly impacts the ability to close the loop and recover valuable resources. Think of this as building the return highway for previously used materials.

Developing Repair, Refurbishment, and Remanufacturing Capabilities: Extending Product Lifespans

Invest in or partner with organizations that can offer robust repair, refurbishment, and remanufacturing services. Repair involves fixing minor damages, refurbishment restores products to a like-new condition, and remanufacturing involves rebuilding products to meet original specifications. These processes are vital for extending the life of products and keeping them in use longer, diverting them from waste streams. This is akin to skilled artisans breathing new life into cherished heirlooms.

Creating Take-Back Programs and Incentives: Encouraging Consumer Participation

Implement take-back programs where consumers can return used products to the manufacturer or retailer. Providing incentives, such as discounts on new purchases or rewards for returning items, can significantly boost participation in these programs. This fosters a sense of shared responsibility for product end-of-life management. This is an invitation to consumers to be part of the solution, not just the end of the line.

Exploring Industrial Symbiosis: Waste as a Resource for Others

Industrial symbiosis involves the collaboration between different companies to exchange waste materials, by-products, and resources. One company’s waste can become another company’s raw material, creating mutually beneficial relationships and reducing overall waste. This is like an ecosystem where different species rely on each other for survival and growth, maximizing resource flow and minimizing waste.

Investing in Digital Platforms and Data Management: Tracking and Optimizing Flows

Utilize digital platforms and robust data management systems to track product lifecycles, material flows, and the performance of circular initiatives. This data is invaluable for optimizing operations, identifying areas for further improvement, and demonstrating the impact of your circularity efforts. In the digital age, accurate data is the compass that guides you through the complexities of a circular system.

Step 4: Building Partnerships and Collaborations for Circularity

| Chapter | Key Metrics |

|---|---|

| 1 | Number of businesses currently implementing circular economy strategies |

| 2 | Amount of waste reduced through circular economy practices |

| 3 | Percentage of cost savings achieved by adopting circular economy principles |

| 4 | Number of new revenue streams generated from circular economy initiatives |

| 5 | Level of customer satisfaction and loyalty due to sustainable business practices |

No single business can achieve a truly circular economy in isolation. Collaboration and partnerships are fundamental to scaling circular approaches and overcoming systemic challenges.

Collaborating with Suppliers: Upstream Circularity

Engage with your suppliers to encourage them to adopt circular practices in their own operations. This could involve working together to source recycled or renewable materials, reduce packaging waste, or improve the recyclability of their products. Ensuring circularity upstream is as important as downstream. A sturdy bridge requires strong foundations at both ends.

Partnering with Customers: Downstream Engagement

Work closely with your customers to understand their needs and to educate them about circular product use and end-of-life options. Co-creating solutions with customers can lead to more effective and well-received circular initiatives. This is a dialogue, not a monologue, ensuring that the circular journey is a shared experience.

Engaging with Waste Management and Recycling Companies: Enhancing Resource Recovery

Forge strong relationships with waste management and recycling companies to ensure that materials collected are processed efficiently and effectively for re-entry into the economy. Collaboration can lead to innovations in sorting, processing, and material recovery technologies. This is aligning with the vital lifelines of the circular system, ensuring nothing unnecessarily falls by the wayside.

Forming Alliances with Research Institutions and Academia: Driving Innovation

Partner with universities and research institutions to stay abreast of the latest innovations in circular economy technologies, materials science, and business models. Collaborative research can accelerate the development and implementation of new circular solutions. These are the think tanks and laboratories of the future, pushing the boundaries of what’s possible.

Collaborating with Policy Makers and Industry Associations: Advocating for a Supportive Environment

Engage with policy makers and industry associations to advocate for supportive regulations, standards, and incentives that foster the growth of the circular economy. Collective action can create a more favorable landscape for businesses transitioning to circular practices. This is about shaping the playing field to make the game of circularity more accessible and rewarding for all players.

Step 5: Measuring, Monitoring, and Iterating for Continuous Improvement

The journey towards a circular economy is not a one-time event but an ongoing process of evaluation and adaptation. Continuous measurement and monitoring are crucial for ensuring that your efforts are effective and for identifying opportunities for further optimization.

Defining Key Performance Indicators (KPIs) for Circularity: Quantifying Impact

Establish relevant Key Performance Indicators (KPIs) to measure your progress towards circularity. These might include metrics such as the percentage of recycled content in your products, the amount of waste diverted from landfill, the lifespan extension of your products, or revenue generated from circular business models. These metrics are your compass and your scorecards, showing you where you are and how you’re performing.

Implementing Data Collection and Reporting Mechanisms: Tracking Progress Consistently

Develop robust systems for collecting and reporting data on your circularity KPIs. Consistent and accurate data is essential for understanding trends, identifying challenges, and making informed decisions. This is the ongoing medical chart for the business’s circular health.

Conducting Regular Audits and Reviews: Assessing Performance

Perform regular internal and external audits to assess the effectiveness of your circular strategies and identify any gaps or areas for improvement. These audits should go beyond mere compliance and focus on the actual impact and efficiency of your circular initiatives. Think of this as a periodic health check-up to ensure all systems are functioning optimally.

Seeking Feedback and Adapting Strategies: Embracing Agility

Actively seek feedback from stakeholders, including customers, employees, and partners, regarding your circularity efforts. Use this feedback to adapt and refine your strategies, demonstrating agility and a commitment to continuous improvement. The market and the environment are dynamic; your circular strategy must be equally adaptable.

Scaling Successful Initiatives and Learning from Failures: The Cycle of Growth

Identify circular initiatives that have proven successful and develop plans to scale them across your organization or into new markets. Equally important is to learn from any initiatives that did not meet expectations. Analyzing failures provides valuable insights that can inform future endeavors and prevent repeated mistakes. This is the iterative dance of innovation, where each step, whether a success or a lesson, contributes to progress.