This article examines the increasing use of modular construction in the wellness industry. Modular facilities offer a versatile and efficient approach to creating health and wellness spaces. This method involves manufacturing components off-site, often in a factory setting, and then assembling them at the final location. This approach contrasts with traditional construction, where most work occurs on-site from the ground up.

Wellness, in this context, encompasses a broad spectrum of services designed to improve physical, mental, and spiritual health. This includes but is not limited to fitness centers, spas, meditation studios, diagnostic clinics, and rehabilitation centers. The demand for such facilities has grown consistently, propelled by a heightened global awareness of well-being.

The Evolution of Wellness Infrastructure

The wellness industry has long relied on conventional construction methods. These methods often entail lengthy timelines, significant on-site disruption, and unpredictable costs. As the industry expanded, these limitations became more pronounced, prompting a search for alternative solutions.

Traditional Construction Challenges

Traditional construction typically involves a sequential process: design, permits, site preparation, foundation laying, structural erection, and interior finishing. Each stage is susceptible to delays caused by weather, labor availability, material shortages, and regulatory hurdles. This often leads to projects exceeding their initial budget and schedule.

- Extended Project Timelines: Conventional builds can span months or even years, delaying revenue generation and business growth.

- On-site Disruptions: Construction sites are inherently disruptive, generating noise, dust, and traffic. This can be particularly problematic for facilities located in residential or mixed-use areas.

- Cost Overruns: Unforeseen site conditions, material price fluctuations, and labor disputes can inflate project costs significantly.

- Quality Control Variability: On-site construction’s quality assurance can be inconsistent, influenced by varying skill levels of different subcontractors and environmental factors.

Drivers for Change

The push for a more adaptable and efficient construction method stemmed from several factors. The need for rapid deployment, cost predictability, and consistent quality became paramount as the wellness market matured.

- Rapid Market Response: Wellness trends can shift quickly. Businesses require facilities that can be deployed or reconfigured promptly to meet evolving consumer demands.

- Geographic Expansion: Operators frequently seek to establish a presence in diverse locations, from urban centers to remote resorts. Modular solutions facilitate easier and faster deployment across various geographical sites.

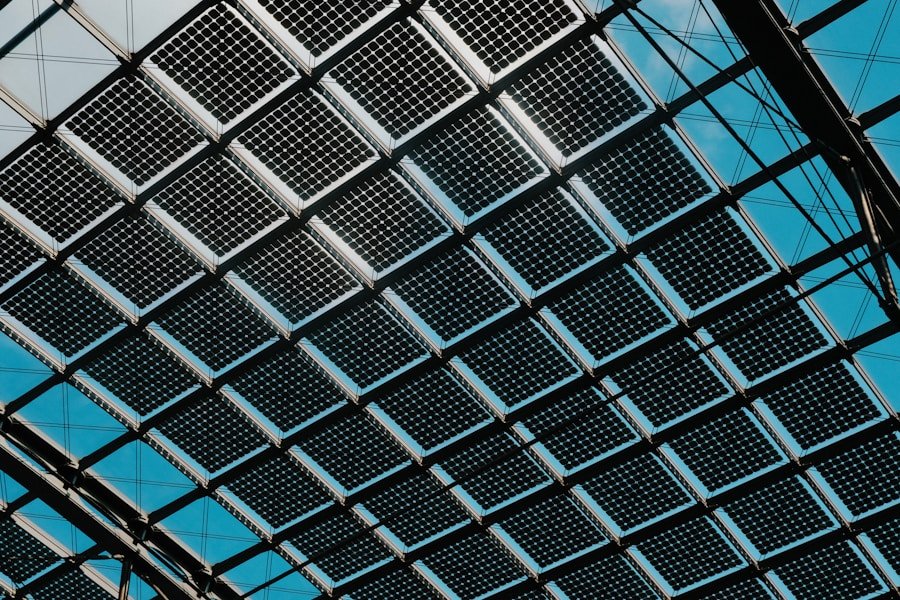

- Sustainability Imperatives: There is an increasing emphasis on environmentally responsible construction practices. Modular building, with its factory-controlled environment, often offers advantages in waste reduction and energy efficiency.

Principles of Modular Construction

Modular construction operates on industrial production principles. Building sections, or modules, are manufactured in a controlled environment, often concurrently with site preparation. These modules are then transported to the site and assembled. This parallel processing is a key differentiator from traditional construction.

The Modular Manufacturing Process

The manufacturing process begins with design and engineering. Once approved, specialized workers construct modules in a factory setting. This controlled environment mitigates many of the risks associated with on-site construction.

- Design and Engineering: Detailed 3D models and blueprints define every aspect of the module, ensuring precision and integration.

- Factory Production: Walls, floors, ceilings, plumbing, electrical systems, and interior finishes are installed within the modules. Quality control checks are constant throughout this stage.

- Transportation: Finished modules are transported to the construction site using specialized carriers.

- On-site Assembly: Cranes lift and position the modules onto a prepared foundation. Connections for utilities and structural integrity are then finalized.

Advantages of Modular Facilities

Modular construction offers several advantages pertinent to the wellness sector. These benefits translate into operational efficiencies and faster market entry.

- Speed of Deployment: Projects can be completed significantly faster, often reducing construction time by 30-50% compared to traditional methods. This allows wellness providers to open new facilities sooner.

- Cost Predictability: Factory-based production reduces exposure to external factors that lead to cost overruns in traditional construction. Bulk material purchasing and reduced waste also contribute to cost savings.

- Consistent Quality: Manufacturing in a controlled environment limits environmental damage to materials and allows for rigorous quality control at each stage.

- Reduced Site Disruption: Most construction activities occur off-site, minimizing noise, dust, and traffic at the final location. This is particularly beneficial for facilities in established neighborhoods or operating during construction.

- Sustainability: Less material waste is generated during factory production. Modules can also be designed for energy efficiency, utilizing advanced insulation and building techniques.

- Flexibility and Relocation: Some modular designs allow for future expansion or even relocation of facilities, offering a high degree of adaptability. This “plug-and-play” capability is especially attractive for businesses that anticipate growth or changes in market demand.

Applications in the Wellness Sector

The adaptability of modular construction makes it suitable for a diverse range of wellness facilities. From small, specialized studios to larger, integrated wellness centers, the approach provides scalable solutions.

Fitness and Exercise Spaces

Modular units are increasingly used for gyms, yoga studios, and specialized fitness training centers. Their rapid deployment is advantageous for operators looking to quickly establish or expand their presence.

- Pop-up Gyms: Modular units can be rapidly assembled to create temporary or semi-permanent fitness facilities for events, corporate campuses, or remote work sites.

- Specialized Studios: Facilities for activities like Pilates, spin classes, or martial arts can be constructed with tailored layouts and equipment integration.

- Expansion of Existing Facilities: Modular add-ons can seamlessly integrate with existing buildings, providing additional space for new equipment or classes.

Health and Diagnostic Clinics

The need for accessible and efficient healthcare infrastructure drives the adoption of modular solutions for clinics, diagnostic centers, and even urgent care units.

- Primary Care Clinics: Standardized layouts for examination rooms, waiting areas, and administrative offices can be efficiently duplicated across multiple locations.

- Diagnostic Imaging Centers: Specialized modular units can house MRI or CT scanners, meeting stringent structural and shielding requirements.

- Vaccination and Testing Centers: During public health crises, modular units have demonstrated their utility in rapidly deploying essential health services.

Spas and Therapeutic Environments

Creating serene and aesthetically pleasing environments is crucial for spas and therapeutic centers. Modular construction can achieve this while maintaining efficiency.

- Treatment Rooms: Standardized, yet customizable, treatment rooms for massage, facials, and other therapies can be manufactured with integrated plumbing and electrical systems.

- Relaxation Areas: Modular units can be designed to incorporate specific atmospheric elements, such as natural light, soundproofing, and custom finishes to create tranquil spaces.

- Hydrotherapy Facilities: With careful planning, modular construction can accommodate specialized plumbing and waterproofing requirements for pools, hot tubs, and saunas.

Challenges and Considerations

Despite its numerous advantages, modular construction is not without its challenges. Prospective adopters must consider these factors before committing to this approach.

Design Limitations

While modular construction offers significant design flexibility, it is not entirely unbounded. The need for standardized unit sizes for transportation and assembly can sometimes impose constraints on architectural design.

- Module Dimensions: Transportation logistics often dictate maximum module sizes, which can limit room dimensions or require creative solutions for larger open spaces.

- Structural Connections: The points where modules connect require careful detailing to ensure structural integrity and aesthetic continuity.

- Foundation Requirements: While the building itself is modular, a conventional foundation is typically still required, necessitating traditional site work.

Regulatory and Permitting Processes

While some jurisdictions are increasingly familiar with modular construction, others may have less streamlined permitting processes. This can introduce delays if local authorities require additional review.

- Specific Building Codes: Ensuring compliance with diverse local building codes for modular units can sometimes be more complex than for traditional builds.

- Inspection Procedures: Local inspectors may need to adapt their traditional inspection regimes to account for off-site manufacturing.

Perceived Quality and Aesthetics

Historically, modular buildings have sometimes been associated with a utilitarian or temporary aesthetic. However, modern modular construction has advanced significantly, offering sophisticated design possibilities.

- Overcoming Stereotypes: Educating clients and the public about the advancements in modular design and quality is an ongoing effort.

- Customization vs. Standardization: Balancing the cost efficiencies of standardization with the desire for unique, custom aesthetics requires thoughtful design.

The Future of Wellness Facilities

| Metrics | Data |

|---|---|

| Number of Modular Facilities | 25 |

| Investment in Modular Wellness | 100 million |

| Employment Opportunities Created | 500 |

| Customer Satisfaction Rate | 95% |

The trajectory of the wellness industry suggests that modular construction will play an increasingly prominent role. As demand for accessible, high-quality wellness services grows, the efficiencies and adaptability offered by modular solutions become even more compelling.

Sustainable Practices

The inherent sustainability advantages of modular construction align well with the growing environmental consciousness within the wellness sector. We can expect to see further innovations in eco-friendly materials and energy-efficient designs.

Technological Integration

Future modular wellness facilities will likely incorporate more advanced smart technologies, from integrated diagnostics to personalized fitness systems, all seamlessly built into the modular units.

Expandable and Adaptable Models

The ability to easily expand, reconfigure, or even relocate wellness facilities will become a standard expectation. Modular construction provides this inherent flexibility, allowing businesses to respond dynamically to market changes.

The embrace of modular construction represents a strategic shift in how the wellness industry approaches infrastructure development. It offers a practical solution to the persistent challenges of traditional building, enabling faster deployment, greater cost predictability, and consistent quality, ultimately supporting a more resilient and responsive wellness ecosystem.